Karolo e thata ea Laminate & Machined

Laminate e tiileng

● Maqephe a Sebetsang Haholo-holo ka Lisebelisoa tsa Motlakase

| Sehlopha | Thermal | Likarolo tse ka Sehloohong |

| 3025 | E-105℃ | E hana ho roaloa |

| 3240 | B-130℃ |

|

| 3253 | H-180℃ | Matla a mechini a phahameng haholo a mocheso o tlase, ha a na halogen |

| D326 | H-180℃ | Matla a phahameng haholo a mechini a mocheso o tlase |

| D333 | C-200℃ | Matla a phahameng haholo a mechini a mocheso o tlase |

| 3242 | F-155℃ |

|

| D327 | F-155℃ | Ho boloka mocheso o matla haholo, V-1 |

| D328 | F-155℃ | Ho boloka matla a mocheso o phahameng, V-0, UL, benzoxazine resin |

| DF204 | F-155℃ | Ho boloka matla a mocheso o phahameng, V-0, UL, resin ea epoxy |

| D331 | H-180℃ | Ho boloka matla a mocheso o phahameng, V-0, UL, benzoxazine resin |

| D329 | H-180℃ | PTI ≥ 500V, V-0, ha e na halogen |

| D338 | H-180℃ | V-0 |

| D330 | B-130℃ | Semi-conductor, e ntšo |

| D339 | F-155℃ | Semi-conductor, e ntšo |

| D350A | H-180℃ | Ho boloka matla a mocheso a phahameng |

| EPGC201 / 202 | B-130℃ | G10 / FR4 (UL) |

| EPGC203 / 204 | F-155℃ | G11 / FR5 (UL) |

| EPGC205 | F-155℃ | Lesela la ho loha le sa reroang le lohiloeng ka khalase |

| EPGC306 | F-155℃ | CTI ≥ 500V |

| EPGC307 | F-155℃ | CTI ≥ 500V,Lesela la ho loha le sa rarahanang la khalase |

| EPGC308 | H-180℃ | Khanyetso e phahameng ka mor'a ho qoelisoa ka metsing |

| DF3316A | C-200℃ | Khanyetso e phahameng ea mocheso |

| DF336 | F-155℃ | CTI ≥ 600V, V-0, ha e na halogen |

● Maqephe a Litšebeliso Tse Seng tsa Motlakase

| Sehlopha | Thermal | Likarolo tse ka Sehloohong |

| D332 | F-155℃ | E hana ho roaloa |

| D3524A | F-155℃ | E ntšo, e thibelang malakabe, e matla haholo |

| DF3524B | F-155℃ | Botenya bo tlase, e thibelang malakabe, e sebelisoa e le thepa ea mantlha |

| D325 | — | Boto ea Kevlar e thibelang ho hlaba, Tšireletso ea ts'ireletso |

| D295 | — | Ho lokisoa ha lesela la Kevlar bakeng sa lihelmete tsa ballistic, Tšireletso ea ts'ireletso |

| D332 | F-155℃ | E hana ho roaloa |

| G3849 | H-180℃ | E sebelisoa lisebelisoa tsa cryogenic (mocheso o tlase ho isa ho -196℃) |

| D3849 | F-155℃ | E sebelisoa lisebelisoa tsa cryogenic (mocheso o tlase ho isa ho -196℃) |

| Z3849 | B-130℃ | E sebelisoa lisebelisoa tsa cryogenic (mocheso o tlase ho isa ho -196℃) |

| DF3313L | B-130℃ | boima bo tlase, boima bo bobebe, Letlapa le letle la ho thibela mocheso |

| DF3314O | F-155℃ | boima bo tlase, boima bo bobebe, Letlapa le letle la ho thibela mocheso |

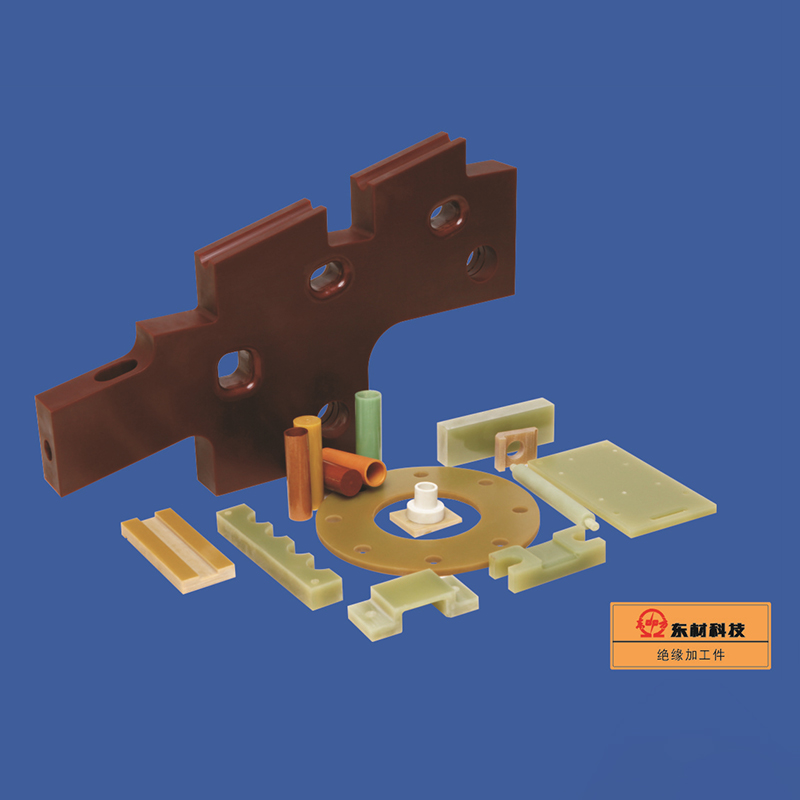

Karolo e entsoeng ka mechini

Likarolo tse entsoeng ka mechini li entsoe haholo-holo ka SMC, BMC, UPGM203 (GPO-3) prepreg, EPGC202 (FR4) le thepa e meng e tala ka ho tobetsa ho chesang kapa epoxy resin/epoxy vinyl resin/unsaturated polyester resin pultrusion forming.

● 工 - Mofuta

● U - Mofuta

● L - Mofuta

● 王 - Mofuta

● Z - Mofuta

Likopo

Likarolo tse telele tsa ho thibela ho qhibilihisa tse entsoeng ka resin tse nang le boholo bo khethehileng tse matlafalitsoeng ka fiber

E sebetsa bakeng sa tlhahiso ea motlakase o chesang (tlhahiso ea matlakala a masepala, tlhahiso ea matlakala a khase)

● Sekotjana sa ho kenya

| Tshebetso | Yuniti | Litekanyetso | |

| 1 | Matla a ho Koba (a tloaelehileng) | MPa | ≥210 |

| 2 | Matla a ho Koba a Pakameng (160℃±2℃) | MPa | ≥170 |

| 3 | Matla a Khatello | MPa | ≥320 |

| 4 | Matla a tšepe | MPa | ≥270 |

| 5 | Khanyetso ea Voltage ea AC | V/60s | 6000 |

● Pad ea ho kenya mocheso

| Tshebetso | Yuniti | Litekanyetso | |

| 1 | Matla a ho Koba | MPa | ≥400 |

| 2 | Matla a ho tenyetseha (a otlolohileng) | MPa | ≥300 |

| 3 | Laminar ea matla a motlakase e otlolohileng (90℃ oli) | MV/m | ≥16.1 |

| 4 | CTI | V | ≥500 |

● Lesale la Selao sa ho Sireletsa

| Tshebetso | yuniti | Litekanyetso | |

| 1 | Matla a ho kobeha | MPa | ≥400 |

| 2 | Matla a ho hatella a otlolohileng laminar | MPa | ≥300 |

| 3 | Tšabo ea mocheso 320℃/1h | __ | Ha ho na ho tlosoa ha lamination, bubble, phallo ea resin |

| 4 | CTI |

| ≥50 |

Mohala: +86-816-2295680

Mohala: +86-816-2295680 E-mail: sales@dongfang-insulation.com

E-mail: sales@dongfang-insulation.com